In the rapidly evolving furniture manufacturing industry, the demand for mass customization has never been higher. As production managers and designers strive to meet the expectations of discerning consumers, digital printing technology emerges as a game changer. This blog explores how leveraging advanced digital printing technology can facilitate mass customization in furniture, enhancing aesthetic appeal while improving operational efficiency.

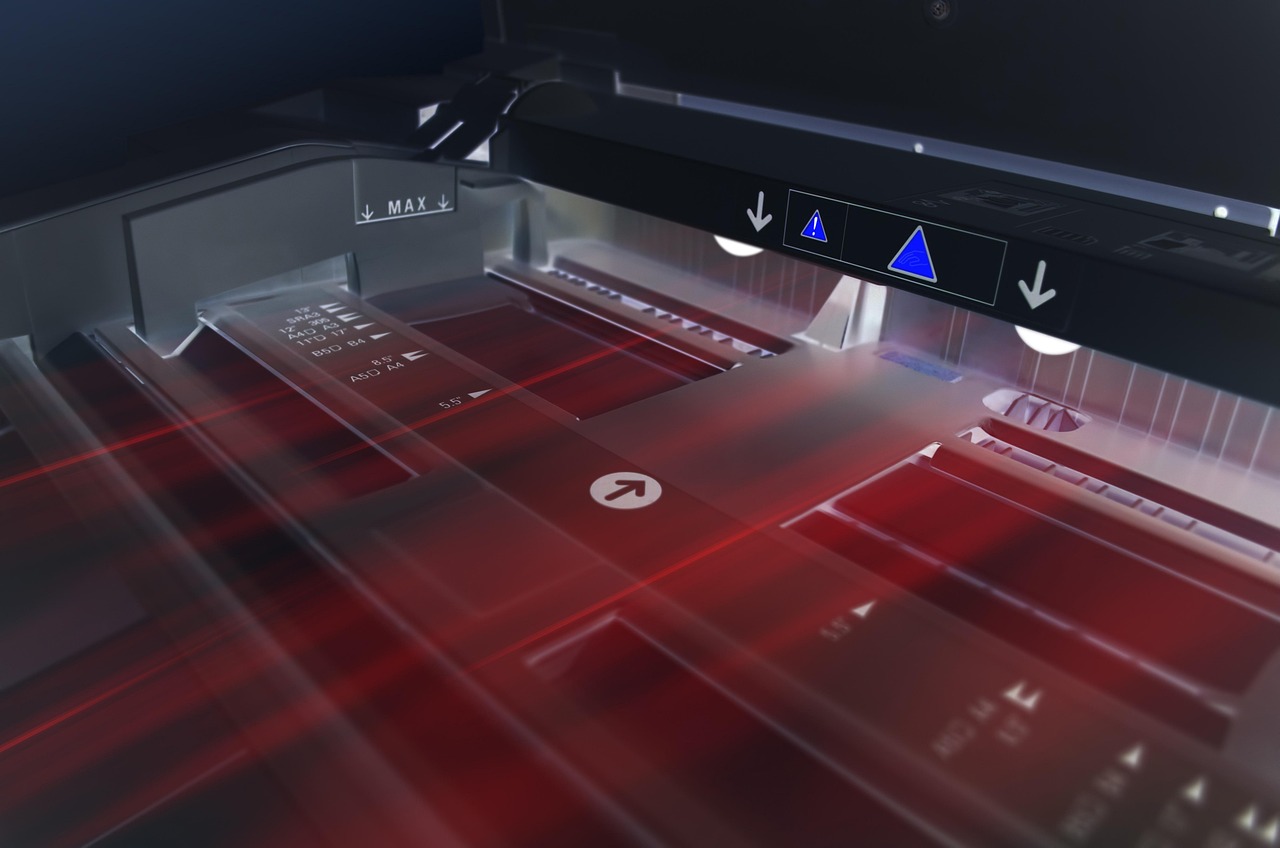

Digital printing technology offers remarkable flexibility, allowing manufacturers to produce customized designs at scale without compromising quality. With capabilities such as high-resolution printing and the ability to replicate intricate patterns, businesses can transform standard furniture pieces into unique, personalized items. This innovation not only satisfies customer demands for individuality but also drives profitability through reduced waste and increased market competitiveness.

"The integration of digital printing in furniture manufacturing can reduce lead times by up to 50%, allowing for a faster turnaround on customized orders." - Prime Colors Technical Team

Companies can leverage digital printing technology to create vibrant graphics, wood grain patterns, and bespoke textures that resonate with modern design trends. This technology has vast applications in the furniture industry, particularly for laminate surfaces, where digital printing can enhance product differentiation and appeal. By adopting such innovative solutions, manufacturers can not only enhance their product lines but also improve customer satisfaction and loyalty.

What Are the Key Benefits of Digital Printing for Furniture Customization?

Digital printing offers several advantages that can significantly impact the production process and the final product quality. Here are some key benefits:

- Enhanced Design Flexibility: Tailor designs to meet specific customer needs, allowing for rapid changes in design without the need for extensive retooling.

- Reduced Waste: Minimize excess materials and production costs associated with traditional printing methods.

- High-Quality Finish: Achieve photorealistic images and consistent color reproduction, ensuring that every piece meets high-quality standards.

- Faster Production Times: Streamline the production process with digital workflows that reduce turnaround times for custom orders.

- Increased Market Responsiveness: Quickly adapt to changing design trends and customer preferences, positioning your brand as a leader in innovation.

The application of digital printing technology in furniture manufacturing not only addresses the challenges of mass customization but also provides a significant return on investment (ROI). By investing in high-quality surface finishes and advanced printing capabilities, companies can enhance their product offerings, attract new customers, and ultimately drive sales growth.

To explore how digital printing technology can transform your furniture production processes, we invite you to request a technical consultation with our experts at Prime Colors. Discover tailored solutions that fit your specific needs and unlock new opportunities for your business.