In the evolving landscape of decorative surface manufacturing, digital printing has emerged as a transformative technology, enabling businesses to create visually stunning and highly customizable products. However, with innovation comes a set of challenges that production managers and designers must navigate to achieve optimal results. This blog post explores how to effectively tackle these challenges while maximizing the advantages of digital printing for decorative surfaces, specifically in the context of industrial coating services in Ahmedabad.

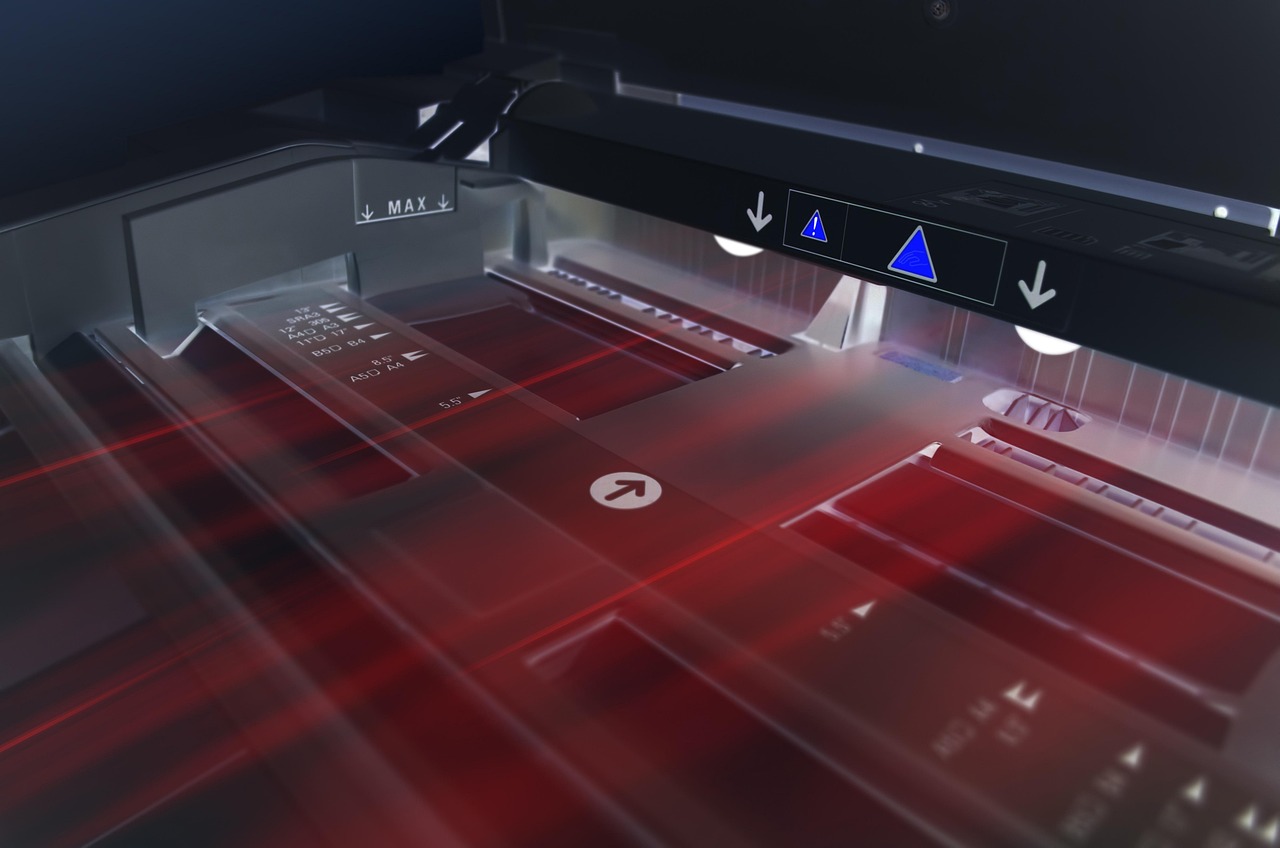

Digital printing technology has revolutionized the way decorative surfaces are produced, offering unparalleled flexibility in design and application. At Prime Colors, we leverage advanced digital printing techniques to provide high-resolution finishes that appeal to both aesthetic and functional requirements. Our solid color coating solutions, PE coatings, and specialized finishes ensure that every printed surface meets rigorous quality standards while delivering exceptional visual appeal. This post will delve into the technical aspects of digital printing, including substrate preparation, ink selection, and post-printing processes, to help you make informed decisions in your projects.

"Investing in high-quality digital printing technologies can enhance product differentiation and customer satisfaction, driving significant ROI." - Prime Colors Technical Team

Understanding the nuances of digital printing can empower manufacturers in the furniture, packaging, and interior design industries to leverage this technology effectively. By integrating digital printing with our specialized coatings, businesses can create unique and durable products that stand out in a competitive market. Considerations such as color matching, surface texture, and durability must be addressed to ensure that the final product not only meets design expectations but also withstands the rigors of its intended use.

How Does Surface Preparation Impact Print Quality?

Surface preparation is crucial in digital printing for decorative surfaces. Properly prepared substrates ensure optimal ink adhesion, vibrant color reproduction, and longevity of the printed design. At Prime Colors, our advanced surface preparation techniques—combined with our PE coating systems—enhance moisture barrier properties and improve overall print quality, making them ideal for high-demand applications such as decorative panels and packaging. For instance, laminating with our solid color coatings not only provides a smooth, printable surface but also adds a layer of protection against wear and tear.

- Enhanced ink adhesion through optimized surface profiles.

- Improved color vibrancy and consistency across multiple print runs.

- Extended durability of printed surfaces, minimizing fading and wear.

- Increased design versatility with custom textures and finishes.

- Reduced production waste by maximizing material efficiency.

In conclusion, navigating the challenges of digital printing for decorative surfaces requires a strategic approach that combines advanced technology with a deep understanding of material properties. By partnering with Prime Colors, you can access cutting-edge coating solutions that not only enhance the aesthetic appeal of your products but also ensure their performance and longevity. Ready to take your surface finishing to the next level? Request a Technical Consultation or Download Our Spec Sheet to learn more about our capabilities and how we can support your unique project requirements.