In today's furniture manufacturing landscape, the demand for customization and aesthetic appeal is at an all-time high. Digital printing technology offers an innovative solution for creating unique furniture designs that not only captivate consumers but also enhance brand identity. This blog explores how industry professionals can effectively leverage digital printing for custom furniture projects, unlocking new levels of creativity and market competitiveness.

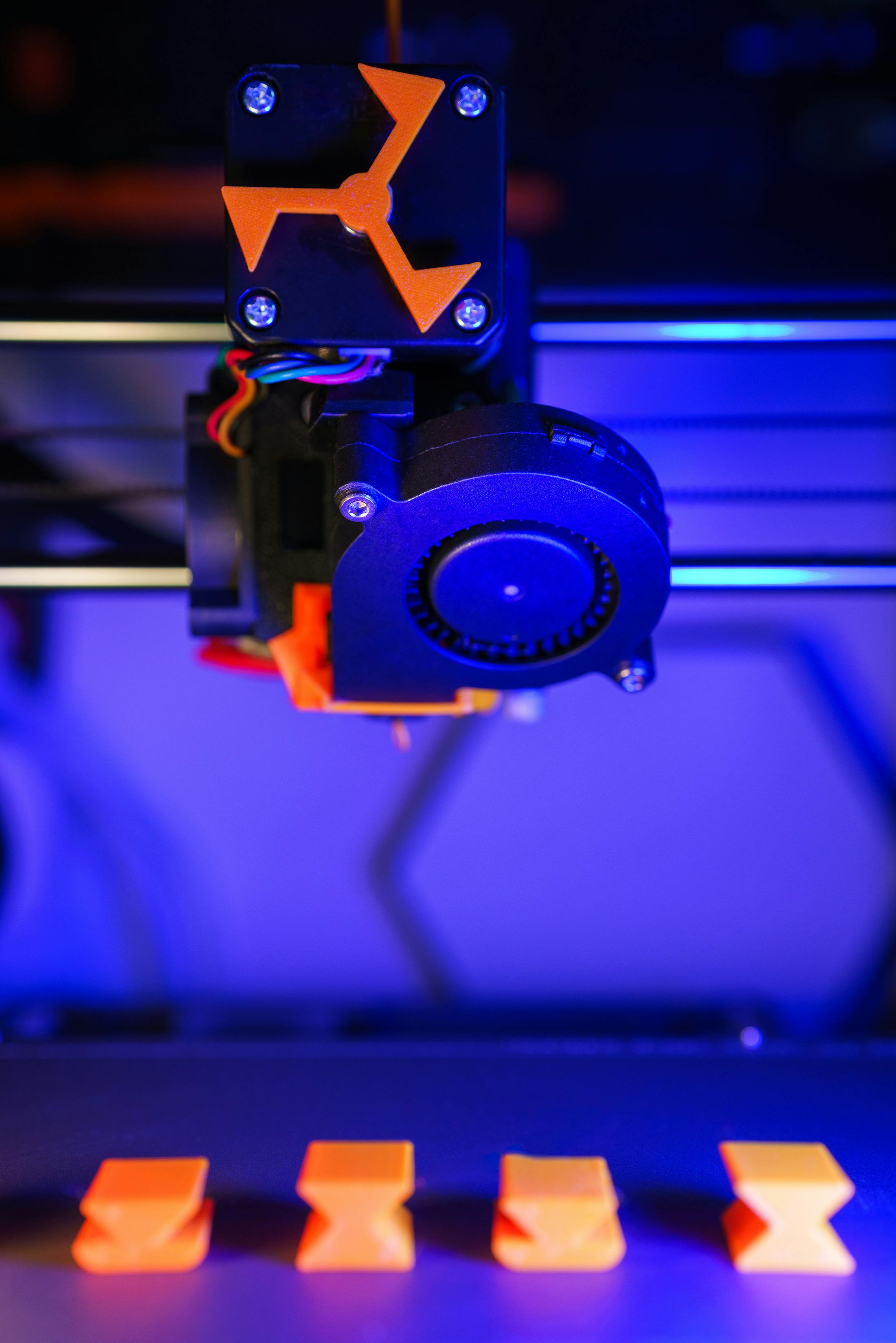

Digital printing allows for intricate designs and custom graphics to be applied directly onto various substrates, making it a game-changer for furniture makers. At Prime Colors, our advanced digital printing capabilities enable the replication of textures, patterns, and colors with exceptional precision. This technology not only enhances aesthetic value but also significantly reduces production costs and lead times, especially for short runs and custom orders.

"Digital printing in furniture manufacturing provides the flexibility to innovate and adapt quickly to market trends, resulting in greater customer satisfaction and loyalty." - Prime Colors Technical Team

The applications of digital printing are vast, from decorative laminate surfaces to custom furniture fronts. With the ability to print high-resolution images and patterns directly onto substrates, manufacturers can create bespoke pieces that cater to individual client needs. This not only enhances the product offering but also allows for a more efficient use of resources by minimizing waste typically associated with traditional printing methods.

How Does Surface Preparation Enhance Print Quality?

Surface preparation is crucial for achieving optimal print quality in digital applications. Our white coating technology at Prime Colors provides a robust base for digital prints, ensuring vibrant colors and sharp details. This specialized coating enhances ink adhesion, resulting in long-lasting prints that withstand wear and tear. A detailed case study from our work with a leading furniture manufacturer demonstrated that using our white coating increased print clarity and durability by over 40% compared to untreated surfaces.

- High-resolution imagery and detailed graphics

- Mass customization for unique client needs

- Reduced production costs with efficient printing processes

- Enhanced durability through superior surface preparation

- Shorter lead times for custom projects

Investing in digital printing technology and high-quality surface finishes is not just a trend; it is a strategic move that yields significant returns. By partnering with Prime Colors, you gain access to innovative coating solutions designed to elevate your furniture products in a crowded marketplace. To explore how our digital printing services can transform your custom furniture projects, request a technical consultation today or download our spec sheet for detailed insights.