In the competitive landscape of the furniture and packaging industries, the demand for durable and aesthetically pleasing products is higher than ever. Decorative laminates, known for their versatility and resilience, are essential in achieving both functionality and visual appeal. At Prime Colors, we understand the challenges manufacturers face in producing high-quality decorative laminates that withstand the rigors of everyday use. This blog will guide you through the intricate process of creating durable decorative laminates, highlighting the technological advancements and coating solutions that ensure longevity and style.

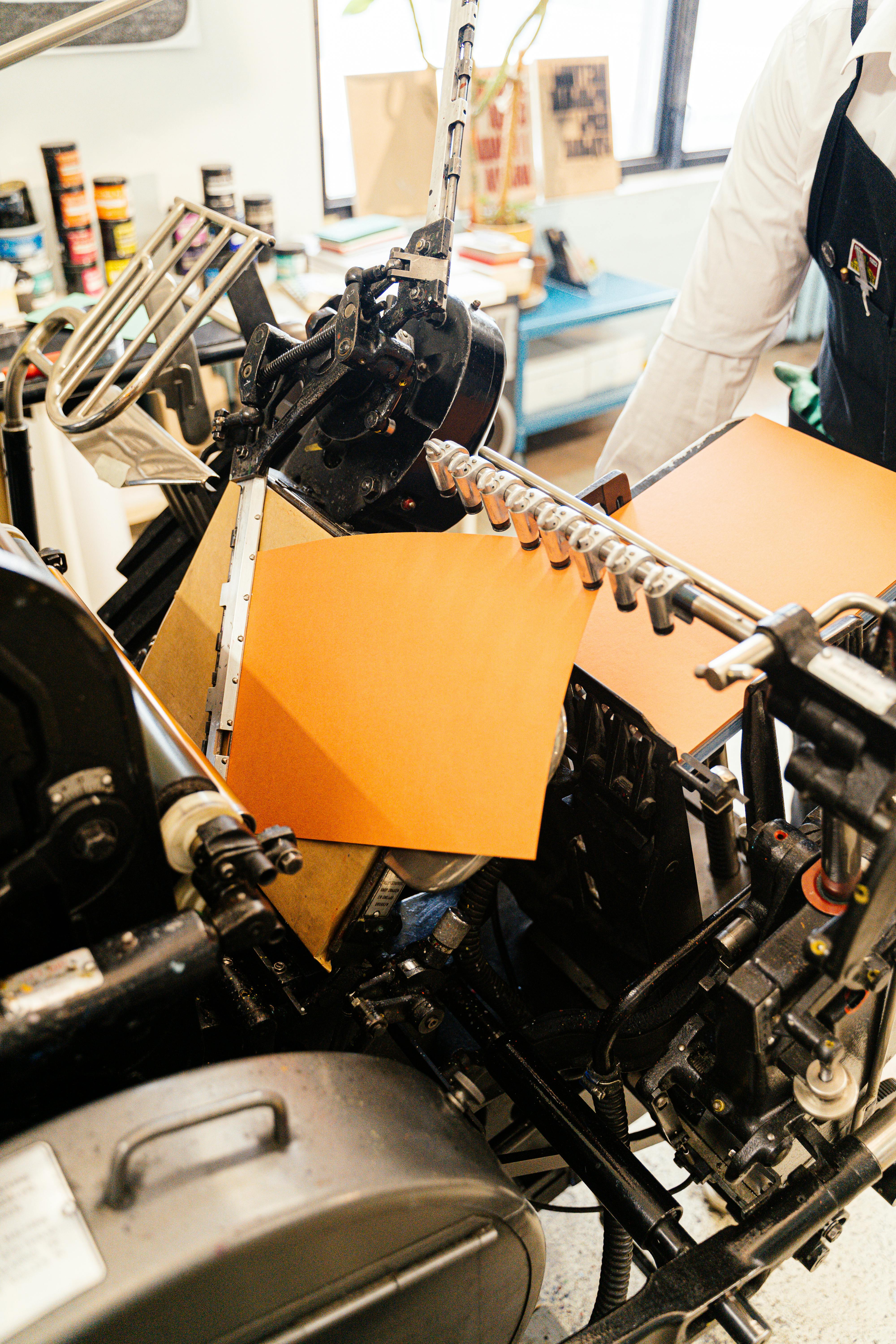

The process of creating durable decorative laminates begins with the selection of high-quality raw materials, specifically decorative paper and thermosetting resins, such as melamine or polyurethane. This combination not only enhances the aesthetic value but also contributes significantly to the laminate's durability. Our innovative solid color coating technology is employed to impregnate the decorative paper with these resins, resulting in a product that is resistant to scratches, heat, and stains. The final laminate is then cured under controlled conditions, ensuring a flawless finish that meets the rigorous standards of various industries.

"Our advanced coating processes enhance the durability of decorative laminates, making them ideal for high-traffic applications." - Technical Expert at Prime Colors

The applications of durable decorative laminates are vast and varied. From luxury furniture and countertops to architectural panels and retail fixtures, these laminates offer an aesthetically pleasing finish while ensuring longevity. Industries such as furniture manufacturing and interior design can leverage our products to create stunning, long-lasting pieces that appeal to discerning consumers. Additionally, with our solid color coating services, brands can achieve vibrant, consistent colors that enhance their product offerings and market presence.

How Does the Impregnation Process Influence Laminate Performance?

The impregnation process is critical in determining the performance characteristics of decorative laminates. By thoroughly saturating the decorative paper with thermosetting resins, we create a non-porous surface that resists moisture and wear. For example, a case study involving a leading furniture manufacturer demonstrated that laminates treated with our proprietary coating technology increased product durability by over 50%, significantly reducing returns and enhancing customer satisfaction. This process not only ensures a robust surface finish but also contributes to the longevity of the product, making it a worthy investment for manufacturers.

- Enhanced Durability: Our coatings provide superior resistance to scratches and heat.

- Versatile Applications: Ideal for furniture surfaces, architectural elements, and retail displays.

- Quality Assurance: Our laminates meet stringent industry standards for durability and aesthetics.

- Custom Solutions: Tailored coatings based on specific client needs enhance product differentiation.

- Cost Efficiency: Investing in high-quality laminates reduces long-term maintenance and replacement costs.

In conclusion, the process of creating durable decorative laminates at Prime Colors involves a meticulous approach combining high-quality materials and advanced coating technologies. By investing in our industrial coating services, businesses can enhance their product quality, reduce lifecycle costs, and improve customer satisfaction. For more information on how our solutions can benefit your specific applications, Request a Technical Consultation or Download Our Spec Sheet today.