In the competitive landscape of industrial coatings, businesses frequently encounter challenges during the coating application processes. From achieving uniform finishes to ensuring durability, these hurdles can significantly impact product quality and operational efficiency. This blog will explore common challenges in coating applications and present effective strategies for overcoming them, helping businesses in the furniture, manufacturing, and packaging industries enhance their production processes.

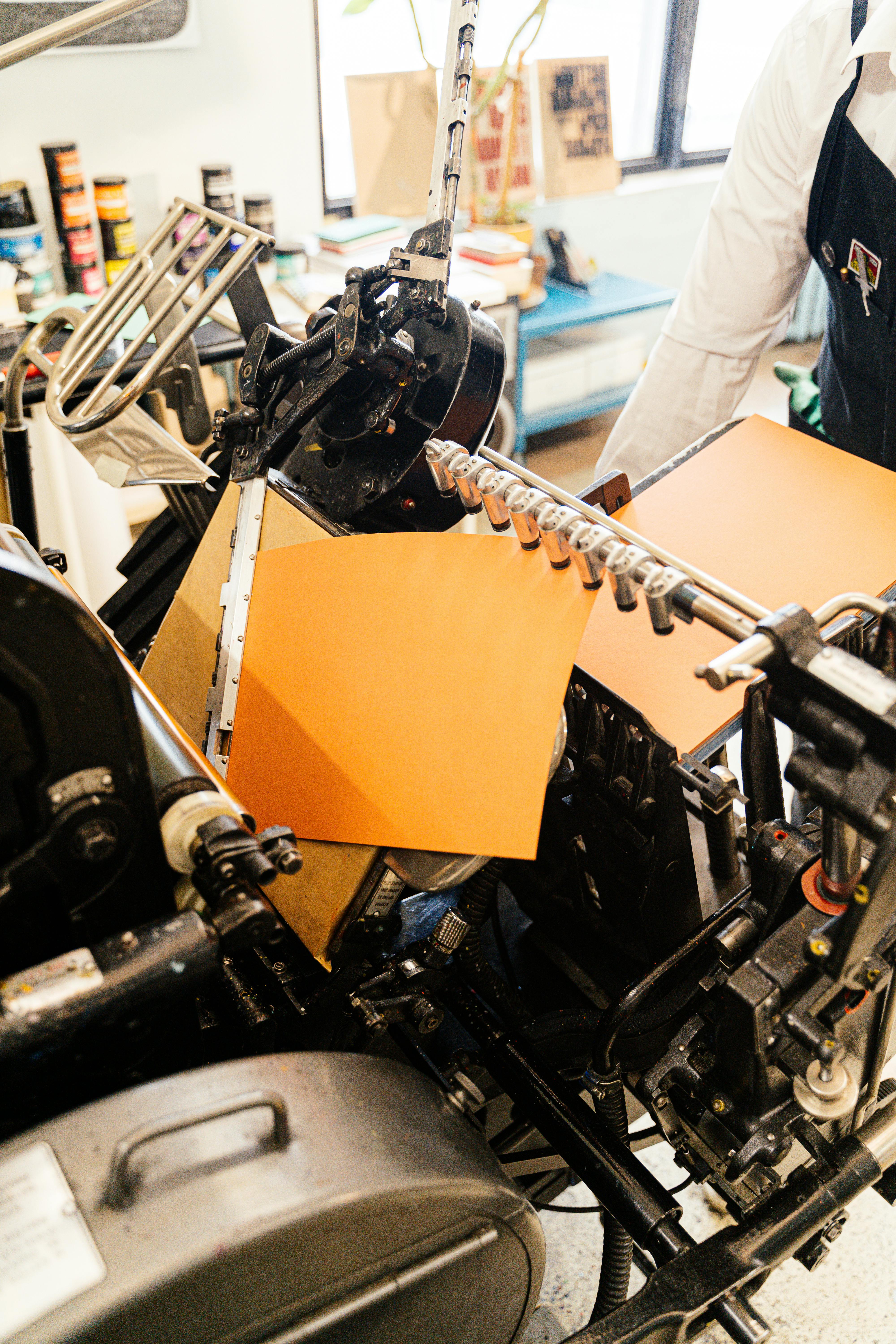

Coating application involves numerous factors, including substrate material, environmental conditions, and coating formulations. For instance, inconsistent application can lead to defects such as runs, sags, or uneven textures. Prime Colors' expertise in solid color coatings and polyethylene (PE) coatings allows us to address these issues effectively. Our advanced technology and meticulous quality control processes ensure that our coatings provide not just aesthetic appeal, but also long-lasting performance. By investing in high-quality surface finishes, businesses can significantly reduce rework costs and improve product longevity.

"Our PE coating process improves moisture barrier properties by over 300%, enabling clients to enhance product durability and shelf life." - Technical Expert, Prime Colors

The application of PE coatings, for example, creates a moisture, grease, and dirt barrier that is crucial for packaging solutions in various industries. This technology is particularly beneficial for food-grade packaging, where maintaining product integrity is paramount. By leveraging our PE coating solutions, businesses can ensure their products remain fresh and safe for consumers, thus boosting their market competitiveness.

How Do Surface Preparation and Application Techniques Influence Coating Quality?

Effective surface preparation is a critical factor that can greatly influence the quality of the final coating. Failure to properly prepare the substrate can result in poor adhesion, leading to premature failure of the coating. For instance, improper cleaning or lack of surface profiling can prevent the coating from adhering correctly. At Prime Colors, we emphasize the importance of meticulous surface preparation and employ advanced techniques to ensure optimal adhesion and durability.

- Enhanced Durability: Our coatings are formulated to withstand the rigors of daily use, ensuring long-lasting performance.

- Versatile Applications: Suitable for various substrates, including laminate papers and HPL surfaces, making them ideal for diverse industries.

- Controlled Quality Parameters: We maintain strict quality control measures to ensure consistency across production batches.

- Improved Aesthetic Appeal: Our solid color coatings deliver vibrant and consistent finishes that enhance the visual appeal of products.

- Cost-Effectiveness: By reducing the need for rework and improving product lifespan, our coatings present a favorable return on investment.

In conclusion, overcoming common challenges in coating application processes is essential for optimizing product quality and operational efficiency. By partnering with Prime Colors, businesses can access innovative coating technologies that not only meet their specific needs but also enhance their market presence. For a deeper understanding of how our industrial coating services in Ahmedabad can benefit your production line, Request a Technical Consultation or Download Our Spec Sheet today.