Elevate your surfaces with our specialized Solid Color Coating service for laminate paper. We transform high-grade décor paper into an exceptionally durable and aesthetically superior material for High-Pressure Laminate (HPL) and Thermally Fused Laminate (TFL) applications. This service is essential for creating modern furniture, countertops, cabinetry, and architectural panels that demand perfect color consistency and long-lasting performance.

Our process involves impregnating décor paper with advanced pigmented resins, which are then cured under heat and pressure. This creates a non-porous, resilient surface that is seamlessly bonded to its substrate. The result is a flawless, uniform finish that offers superior resistance to wear, heat, and stains compared to traditional finishes like paint or veneer.

Key Features & Advantages

Our Solid Color Coating service is engineered for ultimate durability and design precision. We deliver a premium, resilient surface that provides a distinct advantage for high-quality manufacturing and interior design.

- Extreme Durability: The thermoset resin surface is highly resistant to scratches, abrasions, heat, and chemicals.

- Flawless Color Consistency: Achieve perfectly uniform color across vast surfaces, impossible to replicate with paint.

- Custom Color Matching: We match your exact brand colors and design specifications for perfect integration into your products.

- Low Maintenance Surface: The non-porous finish is easy to clean, stain-resistant, and requires no special upkeep.

- Enhanced Product Value: The premium look and feel of a solid color laminate surface significantly elevates the perceived value of the final product.

Choose our Solid Color Coating service to engineer products that stand up to rigorous use while maintaining a flawless, modern aesthetic.

Our Coating & Lamination Process

Our meticulous process guarantees a perfect, permanent bond and a flawless finish, transforming raw materials into high-performance decorative laminates.

01. Resin Impregnation

High-grade décor paper is saturated with custom-pigmented melamine or polyurethane resins for color and strength.

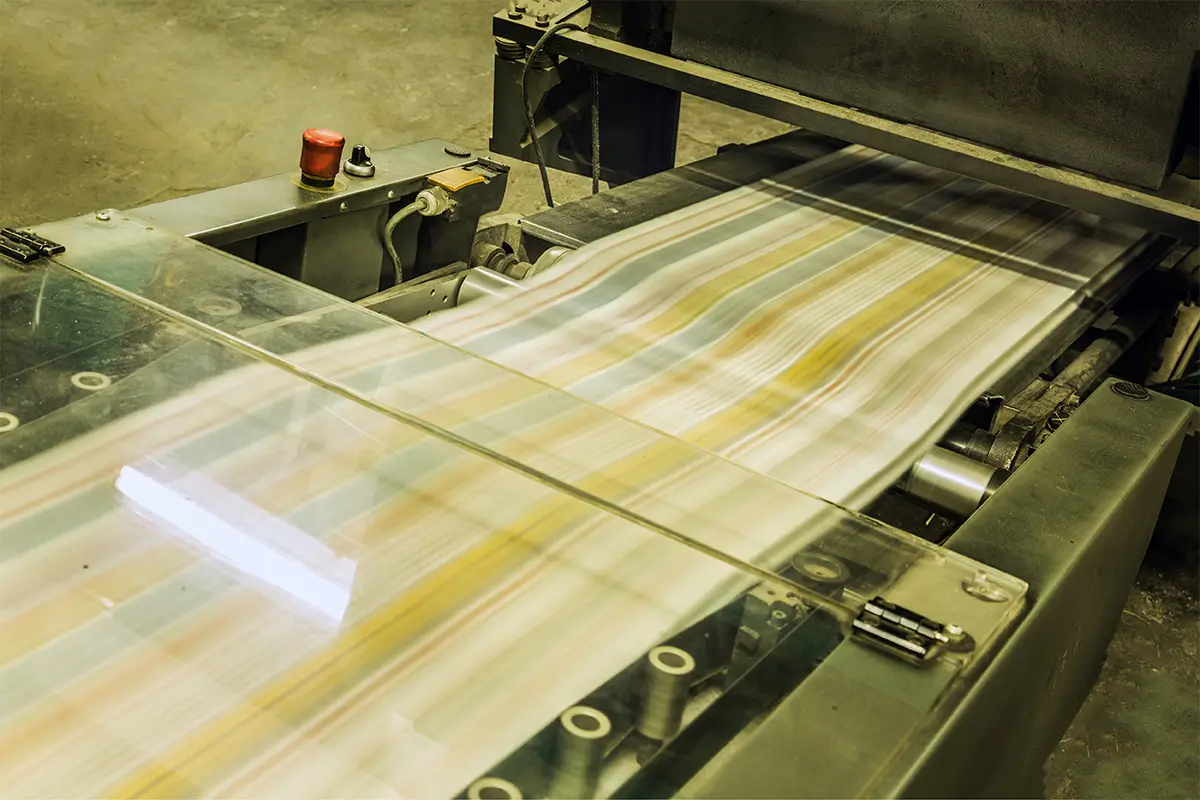

02. Precision Drying

The saturated paper is passed through drying ovens to cure the resin, making it stiff and ready for pressing.

03. Thermosetting

The coated paper is bonded to a substrate (like MDF or particleboard) under intense heat and pressure to create a single, solid laminate sheet.

Applications & Strategic Value

Our Solid Color Coating on laminate paper is the cornerstone of modern, durable surfaces used in a wide range of demanding environments.

This service is ideal for manufacturing kitchen countertops, office furniture, cabinetry, retail fixtures, wall panels, and doors. The strategic value lies in producing goods that offer exceptional longevity and a high-end finish. By ensuring color consistency and superior durability, you enhance your brand's reputation for quality and create products that deliver long-term value to the end-user, reducing replacements and maintenance costs.

Frequently Asked Questions

A painted surface is a layer of paint applied on top of a finished product. Our process involves thermally fusing a resin-impregnated paper to a substrate, creating a single, solid material. This makes it far more resistant to chipping, peeling, and scratching than paint.

Yes. We can achieve a wide range of finishes, from matte and textured to high-gloss. A high-gloss finish often involves an additional UV-cured topcoat during the finishing stage to provide maximum sheen and scratch resistance.

The most common substrates for our coated papers are Medium-Density Fiberboard (MDF) and particleboard. These provide a stable, flat, and cost-effective core for the laminate to be bonded to, making them ideal for furniture and paneling.

The laminate surface itself is non-porous and water-resistant, meaning it will not be damaged by spills. However, the overall waterproofness of the final product depends on how the edges are sealed, as the core substrate (like MDF) can be susceptible to moisture if exposed.